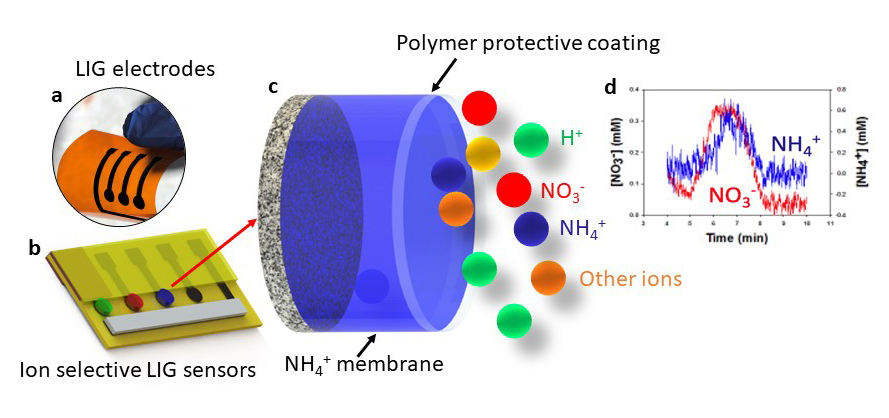

Iowa State’s Jonathan Claussen is studying how plant-based inks can be used to print low-cost, biodegradable and recyclable sensors that can, for example, detect nitrate and ammonium. Larger illustration. Illustration courtesy of Jonathan Claussen.

AMES, Iowa – Researchers will use a new advanced manufacturing grant to develop technologies that use plant-based inks to print low-cost, biodegradable and recyclable electronics for sensors and batteries.

The National Science Foundation (NSF) recently awarded a five-year, $9.15 million grant to support the project and its team of researchers from the University of Chicago, Northwestern University, the University of Illinois Urbana-Champaign, The University of Illinois at Chicago and Iowa State University.

Leading the effort is Junhong Chen, the Crown Family Professor of Molecular Engineering at the Pritzker School of Molecular Engineering at the University of Chicago and the lead water strategist at the U.S. Department of Energy’s Argonne National Laboratory.

Jonathan Claussen, an Iowa State associate professor of mechanical engineering, will collaborate on the project. He’ll work with a doctoral student to develop techniques and technologies that use biobased graphene inks to print electronics for sensors. The grant will provide about $441,600 over five years to support the Iowa State research.

The project is known as MADE-PUBLIC, “Manufacturing ADvanced Electronics through Printing Using Biobased and Locally Identifiable Compounds.”

The grant is part of a $40 million NSF investment in 24 projects advancing biomanufacturing, cybermanufacturing and ecomanufacturing.

“Our investment provides industry with manufacturing tools that currently live only in the laboratory, or the imagination,” said NSF Director Sethuraman Panchanathan in a news release. “Through the convergence of such fields as robotics, artificial intelligence, biotechnology and materials research, future manufacturing will create revolutionary products with unprecedented capabilities, produced sustainably in facilities across the country by a diverse, newly trained workforce.”

Claussen said the grant will support his lab’s development and testing of a variety of printed electrochemical sensors. The sensors could potentially be used to monitor temperature, oxygen and soil nutrients for plants, including those used to produce inks for printed electronics.

“What’s really neat about this is that all of these inks for printed electronics will be biobased,” Claussen said. “We’re looking at biobased substrates to print them on, too. This could circumvent the need for expensive silicon electronics.”

The result could be a low cost way to produce recyclable, biodegradable and carbon-based electronics for a cleaner environment. And that, he said, “is where the future of this industry is heading.”