Key points

- Pre-harvest herbicide applications, when carefully managed, can be a useful tool in weed control and crop desiccation

- Always follow the product label and withholding periods

- Seek advice from grain buyers concerning any specific market requirements prior to use

- Pre-harvest herbicide use should be considered as a part of a wider integrated weed management plan

Growers planning pre-harvest herbicide applications are being urged to arm themselves with the required knowledge to avoid grain rejection from domestic or international markets.

The risks associated with pre-harvest herbicide use for late season weed management or crop desiccation need to be weighed against potential grain market requirements. By adhering to the product label Directions for Use, growers will ensure that any detectable residues will meet Australian Maximum Residue Limits (MRLs). However, importing country MRLs may differ to the Australian MRL. Growers are encouraged to seek advice from their grain buyers regarding any additional market requirements that might impact on their management choices prior to herbicide application.

To guide growers through their decisions, the GRDC has published the Pre-Harvest Herbicide Use Fact Sheet

Late-season application

Application of herbicides close to harvest comes with the risk of detectable residues being present on harvested grain. Herbicides can be used late in the season to manage weeds, prevent weed seed set or to desiccate crops to accelerate or even-up ripening.

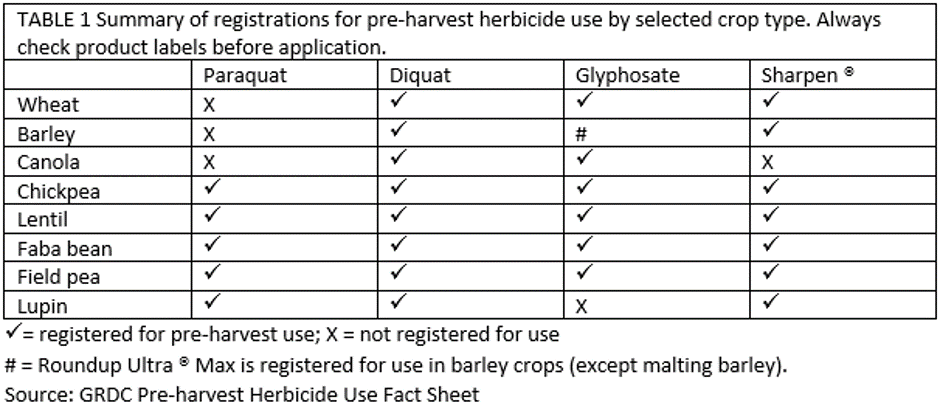

It is the responsibility of growers to adhere to herbicide label recommendations and withholding periods to avoid the presence of unacceptable chemical residues in delivered cereal, pulse and oilseed grains. The Pre-Harvest Herbicide Use Fact Sheet contains basic information regarding chemical registration by crop type (Table 1), but it is recommended to always check chemical labels before use.

MRLs exist for each crop and market. It is important to take into account MRLs for Australia and the country importing the grain, as these restrictions can often vary.

Pulses and pastures

In-crop spray topping with paraquat or glyphosate is often used as a control for a range of annual grasses in pulse crops and pastures.

Chemical use should be considered as a part of a wider integrated weed management (IWM) plan, allowing for alternative weed control techniques. The GRDC’s Integrated Weed Management Manual provides information on the latest tools and techniques for weed management, including cutting crops for hay, break crops and green and brown manuring.

Cereals and canola

Pre-harvest herbicide use in cereals varies by crop type and product label. Individual labels should be checked before application as withholding periods and maximum application rates do vary.

Product acceptance can vary between grain buyers’ policies, and growers should consult with their buyer before any application. This is particularly the case for malt barley crops.

Harvest weed seed control methods such as the use of chaff carts and seed impact mills can be employed as long-term options for control of weeds such as ryegrass. Baling a particularly infested crop can also assist in cost recovery and weed seed control.

Windrowing is also an alternative for growers planning on using desiccation techniques to prepare a canola crop for harvest.

Stewardship

In Australia, the Australian Pesticides and Veterinary Medicines Authority (APVMA) determines MRLs as part of the registration process. The MRL is set based on the application of the pesticide under Australian use patterns (label directions). Not following label directions is illegal and can result in MRL violations. This includes using higher rates or not following timing of application directions and withholding periods.

It is important to remember, the importing country MRLs may differ to the Australian MRL.

Breaches of MRLs can result in grain being rejected by both domestic and export markets.

Grain handlers and marketers regularly conduct testing on grain receivals for residues. The National Residue Survey also conducts ongoing residue testing of grain.