75 years of materials and energy solutions

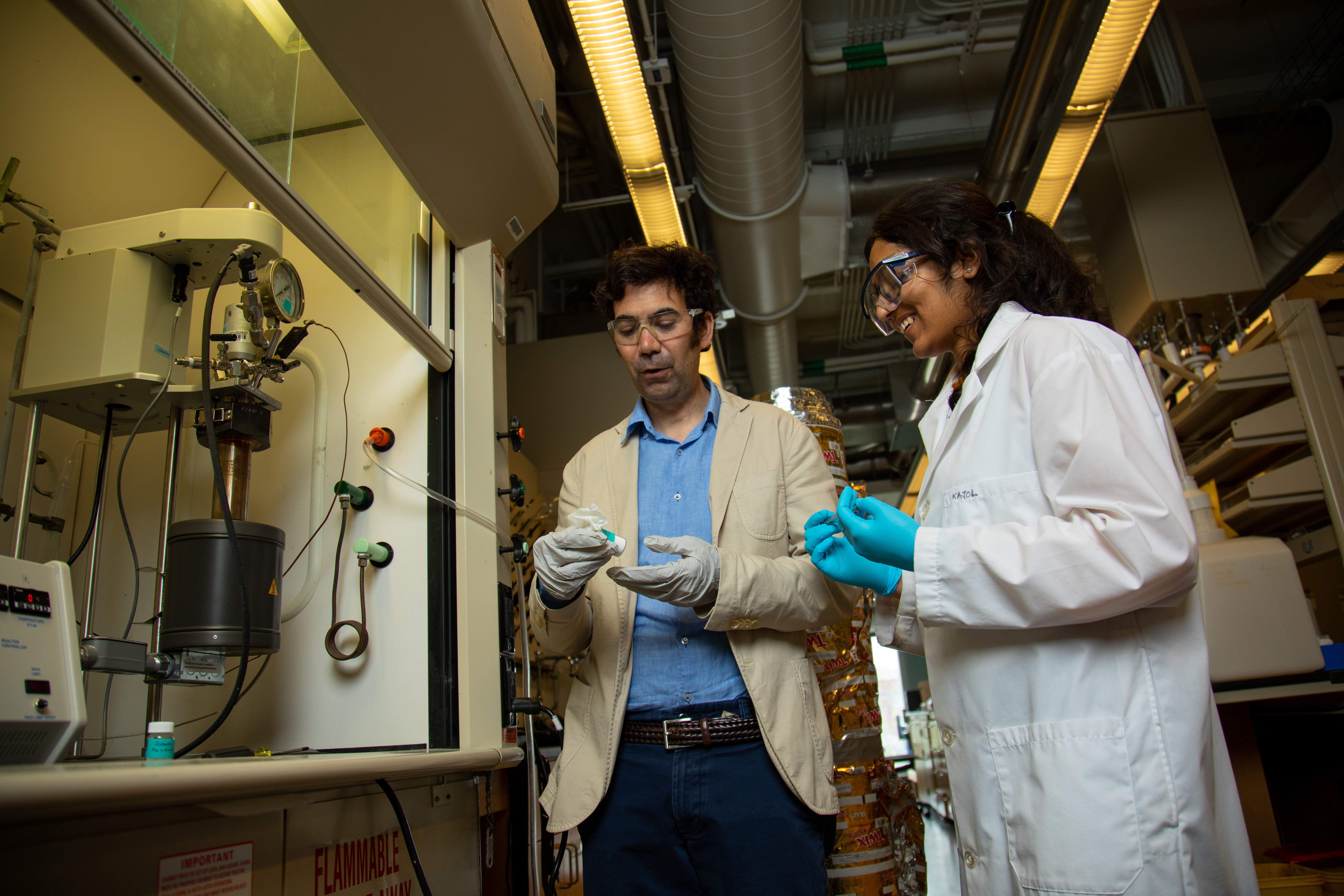

Inside the lab, Aaron Sadow and Kajol Tonk are re-imagining the science of plastics recycling. Photo courtesy of Iowa State Alumni Association.

AMES, Iowa – An integral part of Iowa State University’s legacy of science, engineering and innovation, Ames Laboratory celebrates 75 years in 2022.

Ames Laboratory, and its predecessor the Ames Project, was born as part of the Manhattan Project. Manhattan Project researchers and Iowa State College chemists Frank Spedding and Harley Wilhelm developed a uranium purification method that became known as the Ames Process and is still in use today.

Between 1942 and 1945, the Ames Project produced 2 million pounds of purified uranium for the Manhattan Project out of a building on campus nicknamed “Little Ankeny.” The Ames Project’s uranium helped build the world’s first nuclear reactor. The key role played by the laboratory in the Manhattan Project ultimately enabled both military and peaceful uses of atomic energy.

After the war, the federal government continued funding the research at Iowa State. In 1947, as a result of the Ames Project’s success, Ames Laboratory was formally established on the campus as a national laboratory of the recently launched Atomic Energy Commission.

Ames Laboratory is now part of the Department of Energy and continues to provide a unique educational experience for many students and postdoctoral fellows at Iowa State University.

“One of the best things about our 75 years on campus is the close collaboration we have with research faculty and with students at all levels of their experience. Having national laboratory caliber science imbedded right here at Iowa State provides a proving ground for promising students and early career scientists,” said Adam Schwartz, Director of Ames Laboratory and professor of materials science and engineering at Iowa State University.

Iowa’s National Laboratory is shaping its future much like it shaped its past: by being first, by forging new ground and by using science to meet national and global challenges.

Breaking bonds for a cleaner, greener planet

“Scientists have designed every aspect of plastics’ properties to perform the way we want them to,” says Aaron Sadow, a scientist at Ames Laboratory and professor of chemistry at Iowa State, “except the ‘so-called’ end of life for used plastics. That’s where chemical upcycling of plastics could make a positive impact.”

Sadow leads the Institute for Cooperative Upcycling of Plastics, an Energy Frontier Research Center funded by the Department of Energy, dedicated to re-imagining the science of plastics recycling.

Sadow and his multi-institutional team of researchers are developing new catalysts that turn discarded plastics into more valuable chemicals by breaking the chains at precise positions. These are the building blocks for high-value chemicals like detergents, emulsifiers, fuels, solvents and lubricants. The value of these products provides an economic incentive for plastics recycling and the possibility of a future, less plastic-littered landscape.

Bringing quantum behavior into focus

Located on the edge of Ames, the Sensitive Instrument Facility, a resource shared jointly by Ames Laboratory and Iowa State University, is specially constructed to reduce the acoustic and mechanical vibrations and electric static interference that disturb the accuracy of the electron beam microscopes housed inside. There, discoveries on the atomic scale have enormous potential impact on the future of new and developing technologies.

“All materials have impurities and imperfections that can dramatically impact their performance and reliability, says Ames Laboratory Scientist and Iowa State Professor of Materials Sciences and Engineering Matt Kramer. “As we design and develop materials at the quantum scale, their sensitivity to these defects is magnified. Having the capability to discover the defects and understand how they correlate to device fabrication is pivotal for technology improvement.”

Transforming trash to treasure

Rare earth magnets are the key ingredients of many modern technologies, like electric vehicles, wind turbines and consumer electronics. For the last decade, skyrocketing demand for rare-earths and other critical materials such as cobalt has forced industries to reconsider their use of these materials in manufacturing.

Ames Laboratory’s Critical Materials Institute, a public-private consortium of academic institutions including Iowa State, Department of Energy National Laboratories and industry partners, have been working together to find ways to reduce, recycle, or find substitutes for the materials that are suffering from supply chain interruptions.

The institute speeds economically feasible solutions to manufacturers, and several of them have garnered coveted R&D 100 awards, including a new technology that efficiently recovers rare earths and other valuable elements out of shredded computer hard drives.

The process was recently licensed to TdVib LLC, a Boone, Iowa, based company for scaled up recovery of rare earth oxides. Ikenna Nlebedim, the Ames Laboratory scientist who created the process in 2015, says it’s similar to the Ames Process used by Harley Wilhelm to purify uranium at Ames Laboratory 75 years ago.

Get the full story

Dig deeper into Ames Laboratory history, its current research and enjoy a retelling of Iowa State’s role in the Manhattan Project in the next VISIONS magazine – the official print magazine of the ISU Alumni Association and an exclusive benefit of membership. The award-winning magazine is full of fantastic stories of Cyclones everywhere, detailing how Iowa Staters are making their community, the state of Iowa and the world a better place. Published three times yearly. Want to receive VISIONS in your mailbox? Join the ISUAA as a member today.