When hydrogen moves into steel, it makes the metal become brittle, leading to catastrophic failures. This has been one of the major challenges in moving towards a greener, hydrogen-fuelled future, where steel tanks and pipelines are essential components that must be able to survive in pure hydrogen environments.

Published in Science, the researchers found hydrogen accumulates at microstructures called dislocations and at the boundaries between the individual crystals that make up the steel. This accumulation weakens the steel along these features, leading to embrittlement.

The researchers also found the first direct evidence that clusters of niobium carbide within the steel trap hydrogen in such a way that it cannot readily move to the dislocations and crystal boundaries to cause embrittlement. This effect has the potential to be used to design steels that can resist embrittlement.

Hydrogen is a low carbon fuel source that could potentially replace fossil fuels.

Hydrogen embrittlement

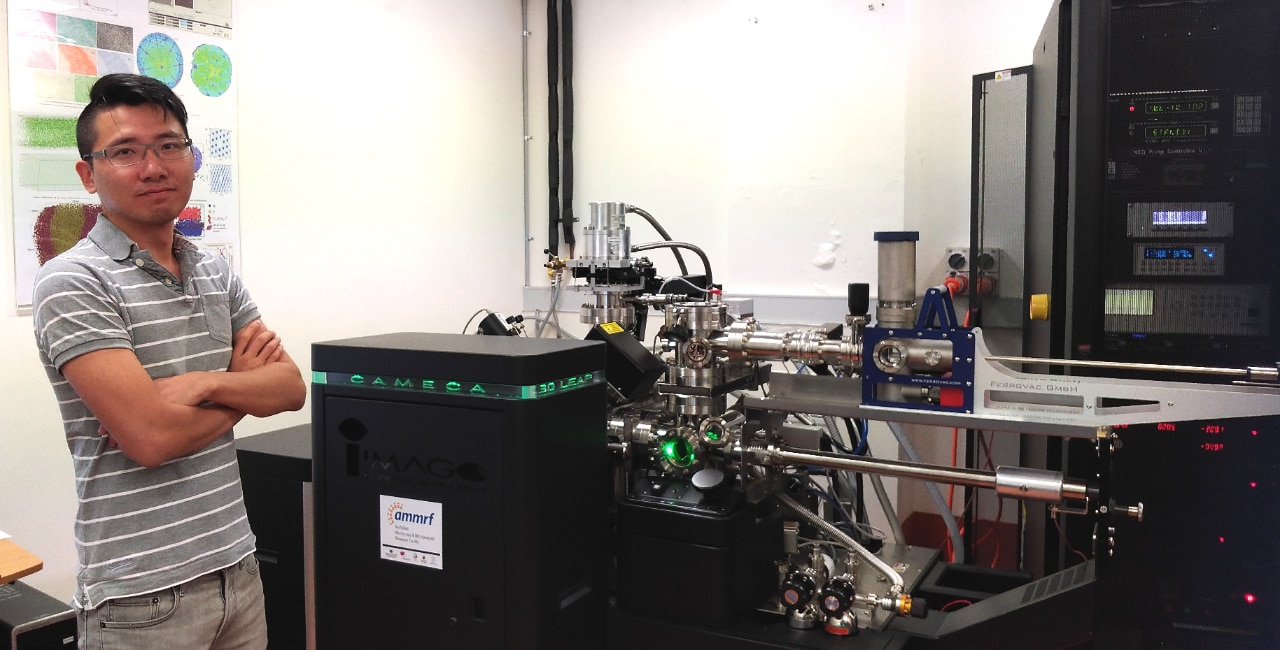

Lead researcher Dr Yi-Sheng Chen from the Australian Centre for Microscopy and Microanalysis and Faculty of Engineering at the University of Sydney said these findings were an important step to finding a safe solution to produce, store and transport hydrogen.

“These findings are vital for designing embrittlement-resistant steel; the carbides offer a solution to ensuring high-strength steels are not prone to early fracture and reduced toughness in the presence of hydrogen,” Dr Chen said.

Dr Yi-Sheng Chen with the Atom Probe Tomography, key equipment that will enable his research.

Senior author Professor Julie Cairney from the Australian Centre for Microscopy and Microanalysis and Faculty of Engineering at the University of Sydney said these findings were a positive step towards implementing clean fuels.

“Hydrogen is a low carbon fuel source that could potentially replace fossil fuels. But there are challenges with the use of steel, the world’s most important engineering material, to safely store and transport it. This research gives us key insights into how we might be able to improve this situation,” Professor Cairney said.

Working in partnership with CITIC Metal, the researchers were able to directly observe hydrogen at microstructures in steels thanks to Microscopy Australia’s state-of-the-art custom-designed cryogenic atom probe microscope.

Declaration: This research was supported by the Australian Research Council and CITIC Metal.