Key points

- Chemical residue limits vary between key domestic and export markets

- While it is a legal requirement to follow chemical label directions, doing so still may not guarantee market access

- Growers and advisers should consult their marketer about acceptable residue levels before applying chemical to crops

- The National Working Party on Grain Protection can provide up to date information on market requirements

Herbicides, fungicides and insecticides are generally accepted as an essential part of successful grain production.

These chemicals are applied from seed preparation to harvest and storage of grain and at virtually every stage in between. As a result, chemical residues may be present on grain when it goes to market.

It is a legal requirement that chemicals used in the Australian farming system and grain supply chain be registered for use on a particular crop and applied according to the label directions.

Maximum residue limits

The Australian Pesticides and Veterinary Medicines Authority (APVMA) sets a maximum residue limit (MRL) for each specific chemical and crop combination to ensure the residue stays below a particular level.

More importantly, however, the chemical residue in the grain commodity must also be no greater than the legislated MRL in the buyer’s jurisdiction.

Failure to comply with a market MRL may result in price penalties or the shipment being rejected and returned to Australia. The marketer or supplier of the grain may also be liable for any costs if there is evidence of non-compliant chemical use or misleading application records.

How markets manage chemical residues

Any market, be it in Australia or overseas, may have its own chemical regulations. Therefore, different MRLs may apply to the same chemical and commodity combination depending on the market it is being sold into.

Overall, there is a trend towards requiring lower chemical residues on grain.

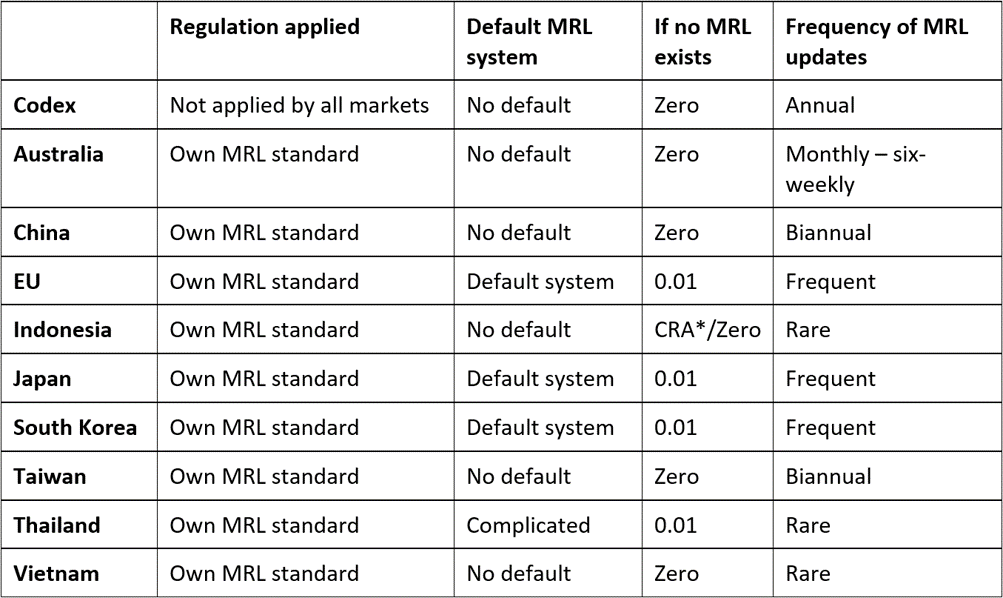

While the international Codex Alimentarius MRLs used to be applied, many markets are now setting their own chemical regulations and MRLs for chemicals (table 1).

TABLE 1. Chemical MRL regulations in selected Australian markets.

Current as at 31 March 2020 – variations exist for specific chemicals. MRLs quoted in milligrams per kilogram of grain.

*Country Recognition Agreement where Indonesia may accept Australian MRLs for some commodities.

Keeping up with the changes

The global patchwork of chemical regulations, zero limit defaults and frequency of updates means growers and their advisers must make sure they stay informed of market requirements.

The National Working Party on Grain Protection (NWPGP) has a role to:

- Provide a link between government and industry on market access related to chemical use

- Provide guidance on chemical use, post-harvest storage and market requirements

- Monitor changes in chemical regulations and their impact on market access

The NWPGP is leading an increase in communication to growers and other stakeholders in co-operation with the GRDC and various government departments.

The goal is for more effective communication between industry participants, including growers, advisers, agronomists, chemical registrants, re-sellers and grain handlers on market requirements in relation to chemical use.

Advice for growers and advisers

Simply applying a chemical correctly as per the label directions may not guarantee the grain meets the customer’s chemical residue limits

It is particularly important to be aware of chemicals that are not acceptable in certain markets or where a zero MRL applies.

Because it is too expensive to sample and test every grain delivery for every possible chemical that is registered, the industry relies on:

- Full compliance of label directions by growers

- A complete and accurate commodity vendor declaration being provided by the grower

- Targeted sample testing before shipment based on perceived risk

Failure to supply and accurately document grain chemical treatments risks a loss of reputation for Australian grain and increased monitoring of Australian shipments, with the cost of this passed along the supply chain.